The Robots Are Taking Over (Your Gears)

Five years ago, if you mentioned "automatic transmission" to a serious mountain biker, you would have been laughed off the trailhead. We curate our cockpits, obsess over engagement points, and pride ourselves on the perfect timing of a downshift just before a technical punch. The idea of handing that control over to an algorithm felt sickeningly counter-intuitive. It felt like a feature designed solely for people who didn't know how to ride a bike.

But the e-MTB landscape is shifting rapidly. We’ve moved past the "arms race" of bigger batteries and more Newton-meters. The new frontier is integration and intelligence. The industry's biggest players aren't just trying to help beginners get up a hill; they are trying to fundamentally change how seasoned riders interact with technical terrain.

The rise of automated shifting ecosystems—specifically from Shimano and SRAM—is the most controversial, and perhaps most significant, development in current e-MTB tech. And if you think it’s just for newbies, you’re missing the point.

Here is a deep dive into the brave new world of smart shifting.

The Two Philosophies: Shimano vs. SRAM

We aren't talking about the clunky, cadence-based auto-shifting offered on budget commuter bikes a decade ago. Today's systems are deeply integrated into the e-bike’s central nervous system, using data from speed sensors, crank torque, cadence, and rider input to make millisecond decisions.

Right now, there are two major camps driving this tech, and they approach the problem differently.

Shimano’s Auto Shift & Free Shift Shimano, paired with their EP801 and EP6 motors, uses their Di2 integration to offer a highly customizable experience. Their system is heavily dependent on speed and cadence thresholds that you can tweak in their app. It’s proactive. If you are coasting downhill and picking up speed, it knows you will need a harder gear when you start pedaling again and makes the shift for you.

SRAM’s Powertrain Ecosystem SRAM’s approach (currently utilizing the Brose motor hardware but their own software brains) is built around their "Transmission" (T-Type) drivetrains. Because T-Type is designed specifically to shift under massive load without crunching, SRAM’s algorithm can be incredibly aggressive. It relies heavily on rider power input and terrain sensing. It tries to keep you in an ideal cadence "window."

Both systems share a goal: removing cognitive load from the rider so you can focus entirely on line choice and body position.

The True Game Changer: Shifting Without Pedaling

If you are an experienced rider, "Auto Shift" (fully computerized gear selection) might still sound appalling for techy trails. The fear of an unexpected upshift mid-crank on a rooty step-up is a valid one.

However, the real revolution isn't necessarily automatic shifting; it’s the ability to shift without moving the cranks.

Shimano calls it "Free Shift." SRAM calls theirs "Coast Shift." It is the single biggest advantage these new smart systems offer to high-level riders.

Consider this scenario: You are bombing down a fast fire road in your hardest gear (a 10-tooth cog). Suddenly, the trail dives 90 degrees left into a steep, punchy, rocky uphill chute.

On a traditional setup, you have to brake hard, lean the bike over, and somehow furiously pedal a half-rotation while simultaneously dumping five gears before you hit the ascent. You usually end up crunching the chain, stalling out, or smashing a pedal on a rock because you had to turn the cranks in a tight space.

With Free Shift/Coast Shift, you hit the brakes for the corner, tap your shifter five times while coasting, and the motor gently rotates the chainring just enough to move the derailleur up the cassette. When you stomp on the pedals to attack the climb, you are already in the perfect gear.

This isn't "dumbing down" the ride; it’s a performance enhancement that allows you to clean sections that were previously awkward or impossible.

The Synergy of Durability and Intelligence

Why is this happening now? Because finally, drivetrain durability has caught up to motor torque.

The elephant in the room with early e-MTBs was chewed-up cassettes and snapped chains. You couldn't trust a computer to shift for you because if it shifted at peak torque (85Nm+), something was going to break.

The introduction of Shimano’s Linkglide and, more significantly, SRAM’s T-Type Transmission, solved this. T-Type actually prefers to shift under load due to the cassette mapping and stout, hangerless derailleur interface. This durability is the foundation that allows automation to exist. The computer no longer has to fear breaking the bike. It can execute a shift exactly when the algorithm demands it, regardless of how hard you are mashing the pedals.

The Verdict for the Enthusiast

Are these systems perfect? No.

For pure, unpredictable technical climbing, many experienced riders will still prefer to turn the full "Auto" mode off, relying instead on their own anticipation. The beauty of these modern systems is that manual override is instant; tap the shifter, and the computer backs off immediately.

But we are rapidly approaching a point where the algorithm is faster and smarter than we are.

It’s okay to be skeptical of giving up control. But don't dismiss it as a beginner’s crutch. The fusion of motor and derailleur into a single, intelligent unit is opening up a new way to flow through terrain. When you stop thinking about gears, you start thinking vastly more about the trail ahead. And isn't that why we ride?

Why Open E-Bike Systems Are the Future of Cycling Innovation

The e-bike industry is booming. Sales are growing across the globe, urban commuters are trading cars for two wheels, and enthusiasts are pushing the limits of what’s possible with electric assistance. But for all this momentum, the industry is being held back by one fundamental problem: closed systems.

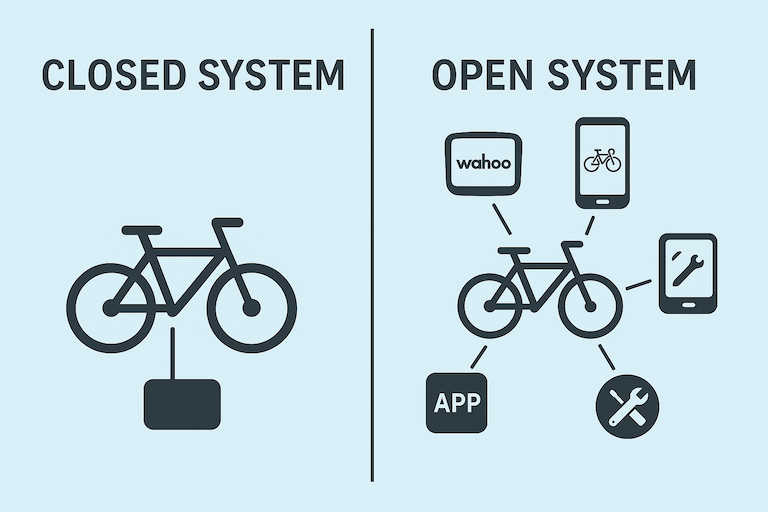

Today, most major e-bike drive unit manufacturers tightly control their hardware and software ecosystems. Motors, batteries, controllers, and even displays are often locked to a single provider. On the surface, this makes sense for a brand trying to deliver a seamless experience. But history shows us that open systems lead to faster innovation, stronger ecosystems, and better results for both companies and end users.

It’s about time for e-biking to follow suit.

Lessons from mobile: Innovation Through Openness

If you look at the history of computing, the parallels are striking. In the early days, computers were often closed systems. Companies like IBM or Apple in its earliest days provided tightly integrated hardware and software, and outside developers had little chance to contribute. This slowed down innovation because only a single company could decide what features would exist, when they would appear, and how fast they could reach users.

But when platforms opened up—think of the personal computer ecosystem in the 80s and 90s, or the explosion of mobile apps after Apple and Google opened their app stores—innovation skyrocketed. Suddenly, thousands of developers and companies could contribute ideas, tools, and features. Competition created better products. Collaboration shortened development cycles. Entire industries were born because the platform was open to participation.

The same principle applies to e-biking. Right now, closed systems mean that only the manufacturer can decide what software features exist, which accessories are supported, or how data flows between devices. If the pace of development seems slow, it’s because it’s bottlenecked by one company’s priorities, and those priorities often don’t match with the wishes of the user.

Lessons From Mobile: Innovation Through Openness

The best example of how openness drives progress comes from the world of mobile. When Apple and Google opened their platforms to outside developers through app stores, the result was an explosion of innovation. Thousands of companies and independent creators suddenly had the freedom to build tools, features, and services that the platform owners themselves would never have imagined.

From fitness trackers to navigation apps to banking on the go, the mobile experience became richer and more useful precisely because the ecosystem wasn’t closed. Customers benefitted from endless choice, and manufacturers benefitted from the added value created by others.

E-biking has the same potential. Right now, closed systems mean that only the manufacturer can decide what software features exist, which accessories are supported, or how data flows between devices. If the pace of development seems slow, it’s because it’s bottlenecked by one company’s priorities, and often those priorities don’t match with the desires of the user. If e-bikes opened up in the same way smartphones did, innovation would accelerate overnight.

Why Closed E-Bike Systems Hurt Everyone

For Customers:

Closed systems limit choice. Riders can’t use 3rd party apps, or the devices they already own. A cyclist with a Garmin or Wahoo head unit may find limited or no integration with their e-bike. Riders who want specific data, custom apps, or performance tweaks are often left frustrated because the system simply doesn’t allow it.

Imagine buying a smartphone where you could only install a small number of pre-selected apps by the manufacturer. That’s essentially what many e-bike owners face today.

For Manufacturers:

Closed systems might feel safe in the short term, but they ultimately slow down progress. Instead of benefiting from a global ecosystem of developers and suppliers who could build on top of their hardware, manufacturers are left carrying the entire innovation burden themselves. That means slower feature rollouts, higher R&D costs, and less flexibility in responding to market demands.

Moreover, customers increasingly value flexibility and integration. A brand that insists on locking people into its own displays, its own batteries, and its own apps risks alienating tech-savvy riders who expect more freedom.

The Case for Open Systems in E-Biking

So what would an open e-bike ecosystem look like? Let’s explore some possibilities.

1. Better Connected Devices

Imagine your e-bike seamlessly integrating with your Garmin, Wahoo, or Hammerhead head unit. Instead of juggling multiple displays, all your ride data—power output, motor assistance, battery status, even predictive range based on terrain and your history—would appear where you want it.

With an open system, integration wouldn’t be left to the goodwill of the motor manufacturer. It would be possible for third-party device makers to plug into standard APIs, giving riders a smoother, more unified experience.

2. New Custom Apps and Smarter UX

Open systems invite developers to build apps and services that manufacturers never considered. Want an app that adapts motor assistance based on your heart rate? Or one that adjusts battery management depending on the GPX route you upload? Or maybe an app designed for indoor trainers that simulates outdoor e-bike rides?

With an open drive unit, these apps could become reality—developed by startups, independent developers, or even the riders themselves. Just as the App Store created an ecosystem of apps nobody predicted, an open e-bike platform would spark creativity and expand what’s possible.

3. More Customization for Riders

Cyclists love customization. From choosing their saddle and tires to fine-tuning gear ratios, riders want control over their machines. E-bikes should be no different.

An open system could allow:

Custom motor profiles (not just eco, commute, race) tailored to specific riders.

Battery optimization based on a route, terrain, or personal preferences.

Accessibility features for riders with disabilities, built by specialists outside the core manufacturer.

Instead of being told “this is how your motor works,” riders could decide what works best for them.

Why Manufacturers Should Care

It’s easy to see why customers would benefit, but why should manufacturers embrace openness? After all, aren’t closed systems a way to lock customers into their brand?

Here’s why it’s actually in their best interest to open up:

Faster Time to Market

By allowing third-party developers to build software and accessories, manufacturers reduce the pressure on their own R&D teams. They can focus on what they do best—making great drive units—while others handle features, apps, and integration.A Larger Ecosystem = More Value

Just as Android’s openness has led to a diverse hardware ecosystem, an open e-bike system would create a network effect. More developers mean more apps, more integrations, and ultimately, more value for the customer. That makes the manufacturer’s platform more attractive, not less.Stronger Customer Loyalty

Paradoxically, openness can increase loyalty. Riders are more likely to stick with a brand if they know they’re not locked in. Just like PC gamers choose certain platforms because they support third-party upgrades, cyclists would choose drive units that allow flexibility and freedom.Future-Proofing

Technology is moving fast. Today’s closed solution might look complete, but in three years it could feel outdated. By embracing openness, manufacturers ensure their systems remain relevant as new devices, sensors, and use cases emerge.

What an Open Drive Unit Could Unlock

Let’s dream a little. If e-bike drive units became open platforms, we might see:

Smart route-based battery management: upload a GPX file, and the system automatically conserves energy for long climbs while giving extra power on sprints.

Performance coaching: apps that analyze both human and motor power to give real-time training feedback.

Seamless smart home integration: your bike communicates with your charging dock, your phone, and your wearable to optimize charging cycles and health data.

Safety innovations: third-party developers creating crash detection, theft prevention, or predictive maintenance tools that work across different e-bike brands.

Community-driven features: imagine open-source motor profiles tuned by expert riders and shared freely across the community.

None of this requires manufacturers to do all the heavy lifting. It just requires them to open the door.

Conclusion: Open Systems Accelerate Progress

The e-bike industry is at a crossroads. It can continue down the path of closed systems, where progress is slow, options are limited, and customers are locked in. Or it can embrace openness, where ecosystems thrive when everyone is allowed to contribute.

Open systems would mean faster innovation, better experiences for riders, lower costs for manufacturers, and a richer ecosystem for the entire industry.

Like it or not, e-bikes are here to stay, and they are becoming more than just bicycles with motors—they’re connected devices, part of a larger digital and mobile ecosystem. And like every digital ecosystem before them, they will reach their true potential only when they’re open.

So Bosch, Shimano, Brose, Fazua, Tq, Yamaha and all others - it’s time to open the ride.